Hudson Company Reclaimed Heart Pine [Chalk Finish] featured on Architizer.com

We were thrilled last week, when The Hudson Company's Reclaimed Heart Pine [Chalk Finish] floors were featured on Architizer.com as one of their featured 'Products of the Day.'

The timing of Architizer's feature on Reclaimed Heart Pine [Chalk Finish] seems especially apropos as we approach the first anniversary of the opening of New York's new Whitney Museum of American Art - a large-scale installation in which The Hudson Company provided over 60,000 square feet of wide plank, Heart Pine floors. To meet the custom design needs for the new Whitney project, The Hudson Company collaborated with the architectural teams at The Renzo Piano Design Workshop and Cooper Robertson Architects throughout 2013 and 2014. At the time of the Museum's opening, Jerry Saltz of New York Magazine described the Whitney's interiors and floors as, 'open, simple, Shaker-like; the wide-plank pine floors are perfect.'

But whether installed on a massive scale (a la the new Whitney Museum) or used in a more intimate, residential application, there is just something special about these particular Reclaimed Wood flooring.

About Reclaimed Heart Pine [Chalk Finish]

Part of what make's our Reclaimed Heart Pine so special is its unique origin story.

For the past two centuries, Longleaf Heart Pine was a predominant standing timber across a large span of the eastern seaboard. Its prevalence and unique properties made it the most widely utilized timber in American construction.

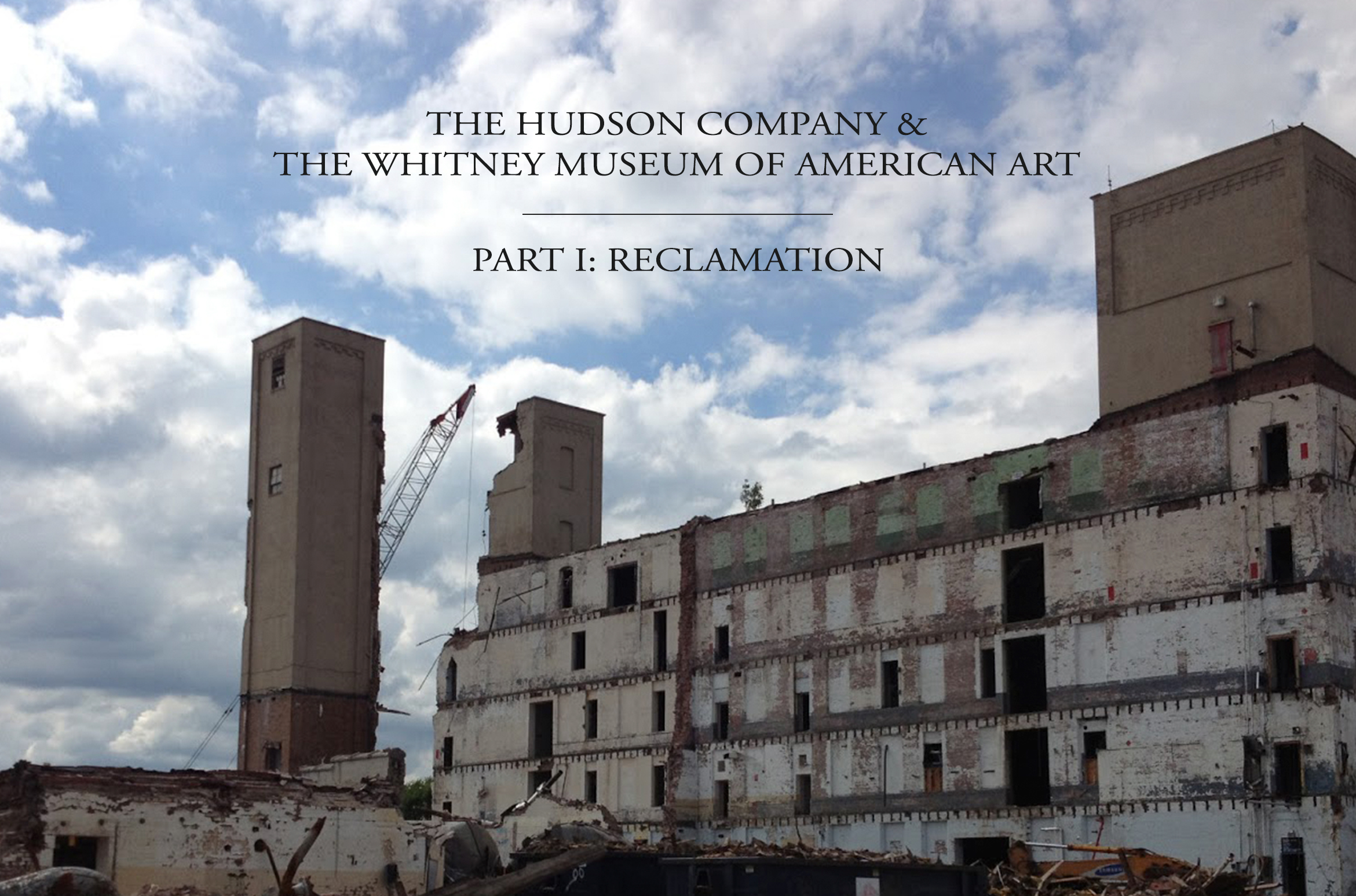

Today, our Reclaimed Heart Pine flooring are sourced from abandoned or de-commissioned factories and warehouses located around the Hudson River Valley, some of which were constructed during the Industrial Revolution. You can learn more about The Hudson Company's reclamation process in our three part series 'Crafting The Whitney Floors.'

Product Specs:

Hudson Company Reclaimed Heart Pine [Chalk Finish] floors are available at dimensions of 3/4" x 4-8" x 2-12'. Tongue & Groove. End Matched. Shown pre-finished in Chalk. Floors are also available unfinished.

Click here to learn more or quote Reclaimed Heart Pine for your next project.

![Hudson Company Reclaimed Heart Pine [Chalk Finish] featured on Architizer.com](https://images.squarespace-cdn.com/content/v1/544e3a5ce4b0117bc5e24e56/1455009562455-E6RKZHPDAXD8UOC1Z5EL/Screen+Shot+2016-02-09+at+10.10.09.png)

![Detail of Reclaimed Heart Pine [Chalk Finish] installed at new Whitney site.](https://images.squarespace-cdn.com/content/v1/544e3a5ce4b0117bc5e24e56/1430382380368-VV5HYF67OCBAKR02XMJI/image-asset.jpeg)

![Reclaimed Heart Pine [Chalk Finish] planks on site at the new Whitney Museum, ready for Install.](https://images.squarespace-cdn.com/content/v1/544e3a5ce4b0117bc5e24e56/1430227561718-EL2LFIEO8W98NBW3DXSA/image-asset.jpeg)