Writing for The New York Times on April 19, Michael Kimmelman described the new Whitney Museum of American Art this way:

'There’s a generosity to the architecture, a sense of art connecting with the city and vice versa...

Inside, irregularly weathered pine floors recycled from old factories temper a language of concrete and steel. Those same industrial materials break up the mass of the building on the outside, by turns refracting and absorbing sunlight, nudging upward, gently, the scale of a swiftly growing neighborhood.'

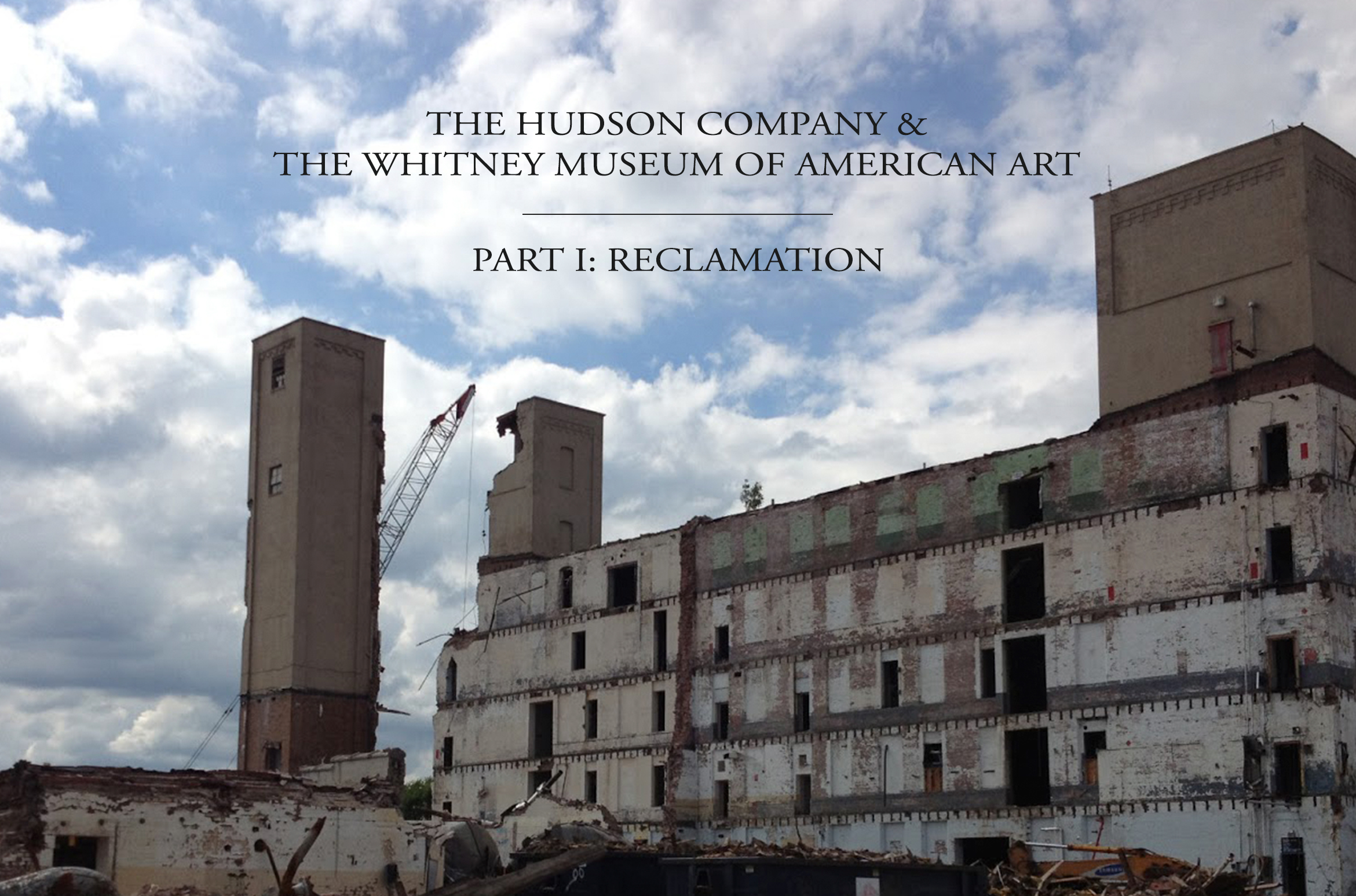

The story behind these 'irregularly weathered pine floors recycled from old factories' is, in fact, a rather remarkable one - the journey of rough, antique, and landfill-bound timbers carefully re-imagined and re-engineered as the flooring for New York City's newest architectural landmark.

Custom Milling The Whitney Floors

After reclaiming the raw timber materials from inactive American factories (Phillip Morris, Maidenform, Paul G. Mehlin & Sons Piano Company), The Hudson Company embarked on the fully-integrated, custom milling process, in collaboration with Cooper Robertson and The Renzo Piano Building Workshop, the museum's lead architects.

The final Whitney installation exceeds 65,000 square feet of Reclaimed Heart Pine [Chalk Finish] flooring throughout all of the galleries and administrative offices. In order to deliver the final product, The Hudson Company custom milled over 270,000 board feet of reclaimed timbers. These sizeable timbers ranged in size from 4” x 17” x 22’ to 11” x 17” x 24’, some weighing in excess of 1,200 pounds.

Once the raw material arrived at our Pine Plains, NY facility, metal detectors were used to locate old fasteners (nails, bolts, screws) embedded within the timbers, and then all unwanted debris is removed by hand.

Next, utilizing our 75 HP fully hydraulic 6” double edge blade saw mill, we milled the timbers into manageable dimensions (1.75" x 10" x 8-20'). Because the Whitney floor was uniquely designed to be 1.5” x 8,” we oversized the the flooring planks to 1.75” x 10" and then kiln dried each plank to 165 degrees Fahrenheit eliminating any remaining insect life and setting the pitch for stability and proper finishing.

From here, the Whitney floors went through the remaining steps of The Hudson Company's hands-on, custom milling process: the planks were re-graded, planed, ripped, molded, and checked for defects and unwanted irregularities before delivery.

Click for more information about The Hudson Company, our team, and for galleries of our reclaimed and custom-milled flooring installation projects.

Click to watch The Hudson Company sourcing and milling video.

![Reclaimed Heart Pine [Chalk Finish] planks on site at the new Whitney Museum, ready for Install.](https://images.squarespace-cdn.com/content/v1/544e3a5ce4b0117bc5e24e56/1430227561718-EL2LFIEO8W98NBW3DXSA/image-asset.jpeg)