Vintage Image of the Noblesville Milling Co. grain storage facility (date unknown).

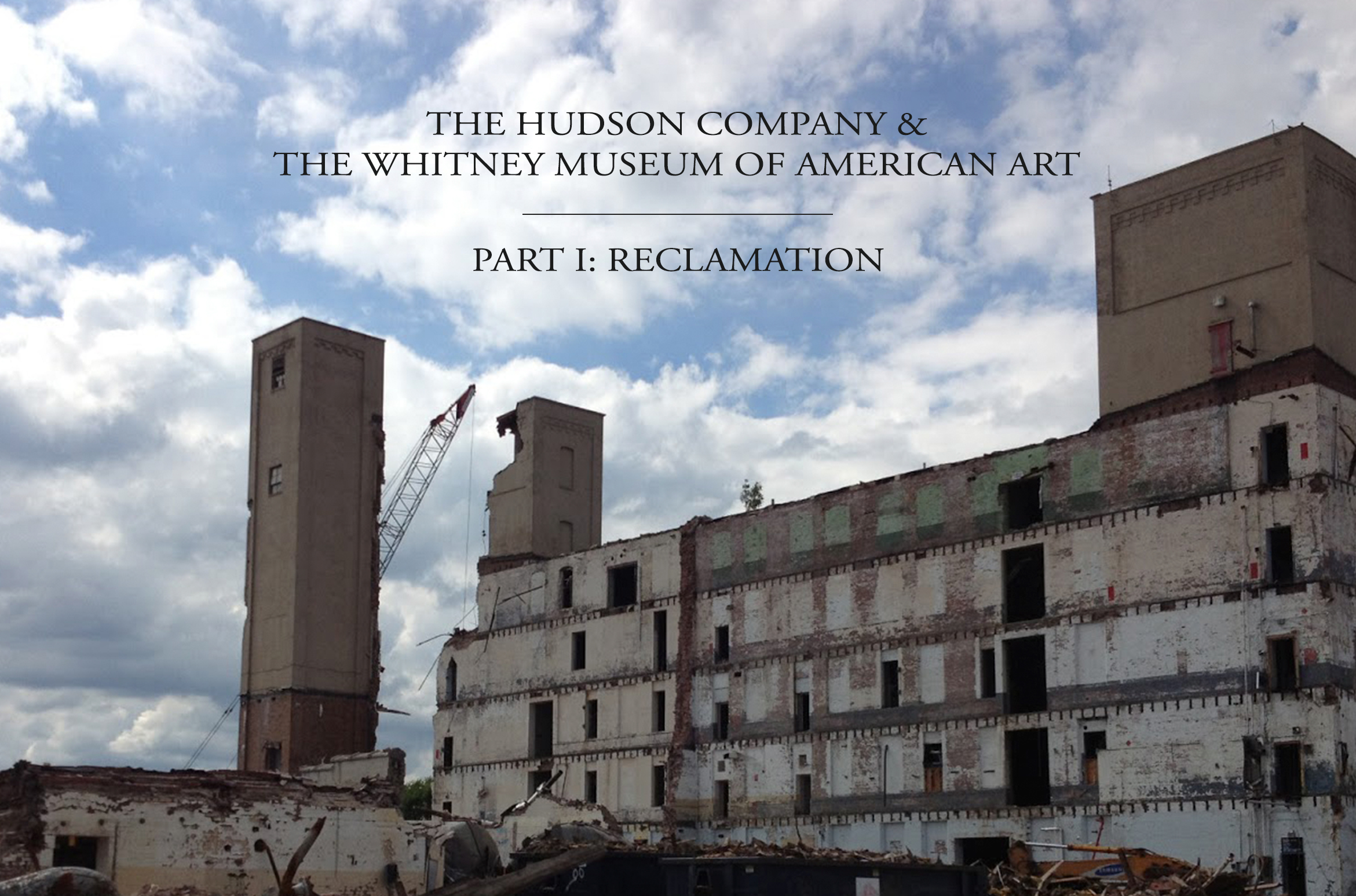

The mill, 2016.

The mill, 2016.

an icon of the American Heartland

This week, The Hudson Company has been on the road - visiting the sites of several historic, decommissioned Midwestern agrarian structures, in search of high-quality, high-character American timber to reclaim. One of the most interesting finds this week has been 'The Model Mill' and grain elevator in Noblesville, Indiana (pictured above and below).

Built in 1901, the mill was an essential part of the economy in Hamilton County and, for over a century, the iconic structure has been both a physical and symbolic icon for Noblesville and the surrounding farming communities. The mill was originally built to hold 350,000 bushels of wheat, but the area's wheat yields were so plentiful that, by 1911, the facility was expanded to hold a capacity of 700,000 bushels. According to David Heighway, of The Hamilton County Business Magazine, the mill was built in a a style of construction called, "cribbing [wherein] boards are [simply] stacked and nailed together." A 1914 article in The Indianapolis Star took note of the Noblesville mill and elevators, remarking that, "These structures tower above the other buildings of the town and are admired by everyone passing through the city.”

700,000 Board Feet of Reclaimed Heart Pine

After changing ownership several times in the 1950s, 60s, and 70s, The Model Mill was eventually decommissioned and has sat abandoned for many years. In 2015, local officials decided that the historic mill and grain elevators would finally be taken down.

Luckily, much of the mill's original construction material has been well-preserved and will be now be diverted from the waste stream and reclaimed by The Hudson Company. From Noblesville, the 700,000 board feet of Reclaimed Heart Pine will be transported to The Hudson Company Mill in Pine Plains, NY were it will be re-milled and added to our growing inventory of reclaimed wood flooring, paneling, beams and joists.

The end result of this reclamation process will be 700,000 board feet of custom re-milled Reclaimed Heart Pine [New Face, Chalk Finish] flooring, like the flooring milled for and installed at New York's new Whitney Museum of Modern Art (completed in 2015).

Click here to learn more about (or to schedule a visit to) The Hudson Company's FSC-Certified lumber mill in Pine Plains, New York.

Pristine American Heart Pine, reclaimed from Noblesville grain facility.

On the road in the American Heartland.

![Hudson Company Reclaimed Heart Pine [Chalk Finish] featured on Architizer.com](https://images.squarespace-cdn.com/content/v1/544e3a5ce4b0117bc5e24e56/1455009562455-E6RKZHPDAXD8UOC1Z5EL/Screen+Shot+2016-02-09+at+10.10.09.png)

![Detail of Reclaimed Heart Pine [Chalk Finish] installed at new Whitney site.](https://images.squarespace-cdn.com/content/v1/544e3a5ce4b0117bc5e24e56/1430382380368-VV5HYF67OCBAKR02XMJI/image-asset.jpeg)